Viapiana Customs

/Text : Mathieu @BestShopsInTown

Photos : Mathieu @BestShopsInTownWith each new city, new opportunities arise for me to discover new shops and meet new people. On my last trip to Toronto, I already knew one of my first destinations. This place had been recommended to me by Arthur @superstitch as one of the must-see places. This place is none other than the workshop of certainly one of the best denim makers in the world. And I weigh my words when I say that the man in question is talented.

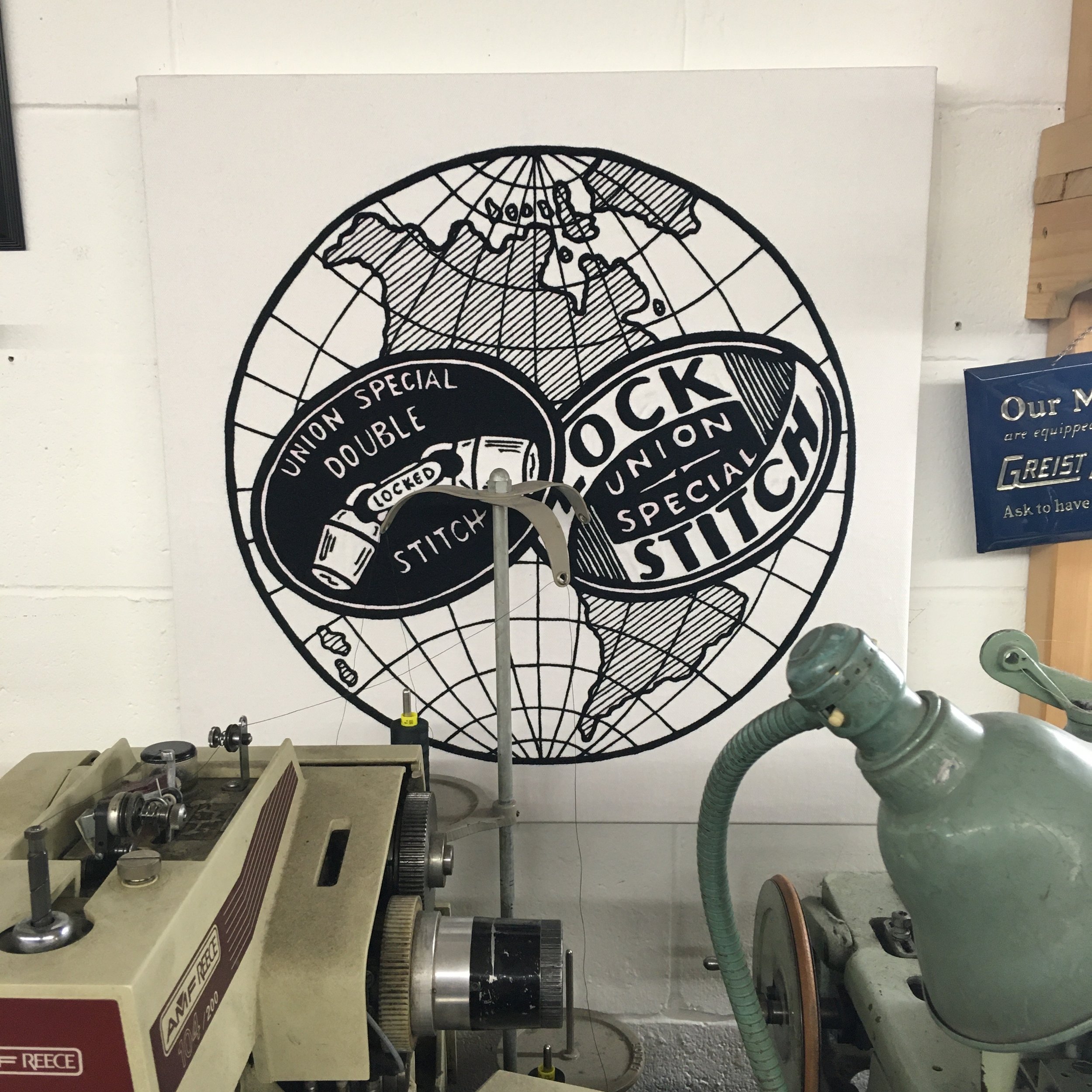

Welcome to Viapiana Custom. This workshop located in the basement of a building is a landmark for insiders and true enthusiasts of the famous “toile de Nîmes”. But not only, because the man is gifted and he knows how to work with different materials. I am welcomed by the master chef, Mr. Benjamin Viapiana. The place impresses me at once with the number of sewing machines and the atmosphere which reigns there. We feel the know-how and that each tool and machine has a specific use. It is very simple, everything here is made by hand. We are not talking about automation but about know-how, because all the pieces are made "from scratch" by Ben.

But rather than a long speech, let me share with you the fascinating interview of Ben to learn more about his career and his art:

1- Can you introduce yourself?

I’m Benjamin Viapiana and I was born in Toronto, Canada. My father is from Italy and my mother is Canadian.

2- Why and how did you create Viapiana Custom?

My dad is a tailor and he started to become a tailor when he was five years old in Italy and his business is called Viapiana Custom Tailor so I, you know, remixed it a little bit to call Viapiana custom denim. Because I focus more on workwear and less on classic menswear.

3- Why did you choose Denim?

It was kind of almost a joke at first. When I was 16, I asked my dad: “OK I'm ready, teach me to do some tailoring”, and he said, “it's too late”. And he was pretty serious because as I said, he started when he was five years old.

4- Did he learn from himself?

No, well you know, when you start school, this is back in 1947, he would have started school when he was five. So when you start school than in a small town when you're poor, the day you start school is the day you start your job.

So his brother was Carpenter, another brother was a tinsmith, the other was a hairdresser and he was the tailor.

So yeah, when I was 16 I said “Ok, teach me, I'm ready” and he said, “it's too late”.

So kind of like half out of spite, half like I can do it anyways, I decided to try something a little bit different and do jeans.

And there was one like, I don't even know if he remembers when he said it or not, but there was one time when he kept on asking like “why you wear your jeans like this, pull it up, you dress a little bit nicer”. So one day he said, “if you can make it, you can wear that wherever you want”. So I said “OK fine”. Then I remember I went to grab the car keys right away, took the car, went to the fabric store, bought some material, some denim, and then, went to the second-hand store and bought an old pair of jeans.

That was OK.

I took it apart, cut the new material, and made them. It was a disaster.

So that's kind of the beginning of where it came from.

5- Do you have a real passion for denim fabrics and something like that?

That's the funny thing, is that most of the denim brands or people in the denim industry, will have that special story, like when “I was seven, I touched my first Levi's and I jez in my pants or even like that”.

But no, I don't have that when I told my dad I'm gonna make one. I didn't know what denim was, I just knew that I liked to wear jeans. You know, like who cares?

And I didn’t even know stretch, not stretch, selvedge, not selvedge, I didn't know what that is. I only learned about selvedge denim when I was already making jeans.

6- When did you start your business, at 16?

Yeah, so I mean from about 16 to 18 or so, I was just experimenting with stuff like I would make a lot of jackets, I would take like a hoodie with the zipper in the front and I would take the pattern and make it with Tweed with some silk lining or something like Old Streetwear style.

And yeah, I experiment with lots of stuff like this.

7- Did you already have machines to do that?

My dad has 12 machines or so to make suits and dress pants, shirts and whatever so I was able to use those and he ran the business from home so the machines were always super close.

8- And over 18?

When I was 19, I moved to Thailand where I went on vacation, and then I ended up staying. So that was from 19 until 30.

When I went there, I still wanted to make stuff and I started to make more jackets when I was there, but no one can wear jackets in Thailand, it’s too hot.

9- Did you learn everything by yourself too?

Pretty much yeah.

10- Never go to school to learn some techniques?

No, no, I never went to school for that. I never went to university or college or anything. I don't have time for that or money.

11- From the beginning, you knew that you wanted to create something with your hands?

No, no, no idea. When I was young I thought I was going to be a pro skateboarder, this is why I’m still wearing Vans all day.

But I had no idea. I just knew that I liked doing it. So when I went to Thailand, the first day I got my apartment I also went out and bought the sewing machine.

Just 'cause you know if I'm going to be there, I'm going to have one.

And then one turn to two turns to three, and then after that, I bought 5 all in one shot. That was after about two years of being in Thailand just making jeans with like single needle only.

Then I was like I want to make this a business but I gotta really like go for it. So I quit my English teaching job, which I found randomly, and bought the rest of the important machines, another five of them, and went from there.

12- At that time, you were already selling garments to your friends?

It was all word of mouth. Even to this day, the best way is word of mouth. You know someone buys something and feels good about it and they tell their friends.

13- Did you already own old machines?

No, at that time I had no idea, I thought brand new was better. The first machine I ever bought was a brand new white machine. I thought it was the Juki but it actually spelled it wrong as a fake Juki is called Juiki. So I had that one and then I also had a fake, it was like just some Chinese brand-like serging machine. It's like the Singer 81, but it was like green and I think was called Flying Horse.

14- This machine, did it allow you to make pants?

That serger was garbage, so I literally used it once and I felt stupid for buying it, so I never used it. The white machine it's still in use today. I gave it to a Vietnamese guy, a Vietnamese refugee in Thailand and he's still using it today.

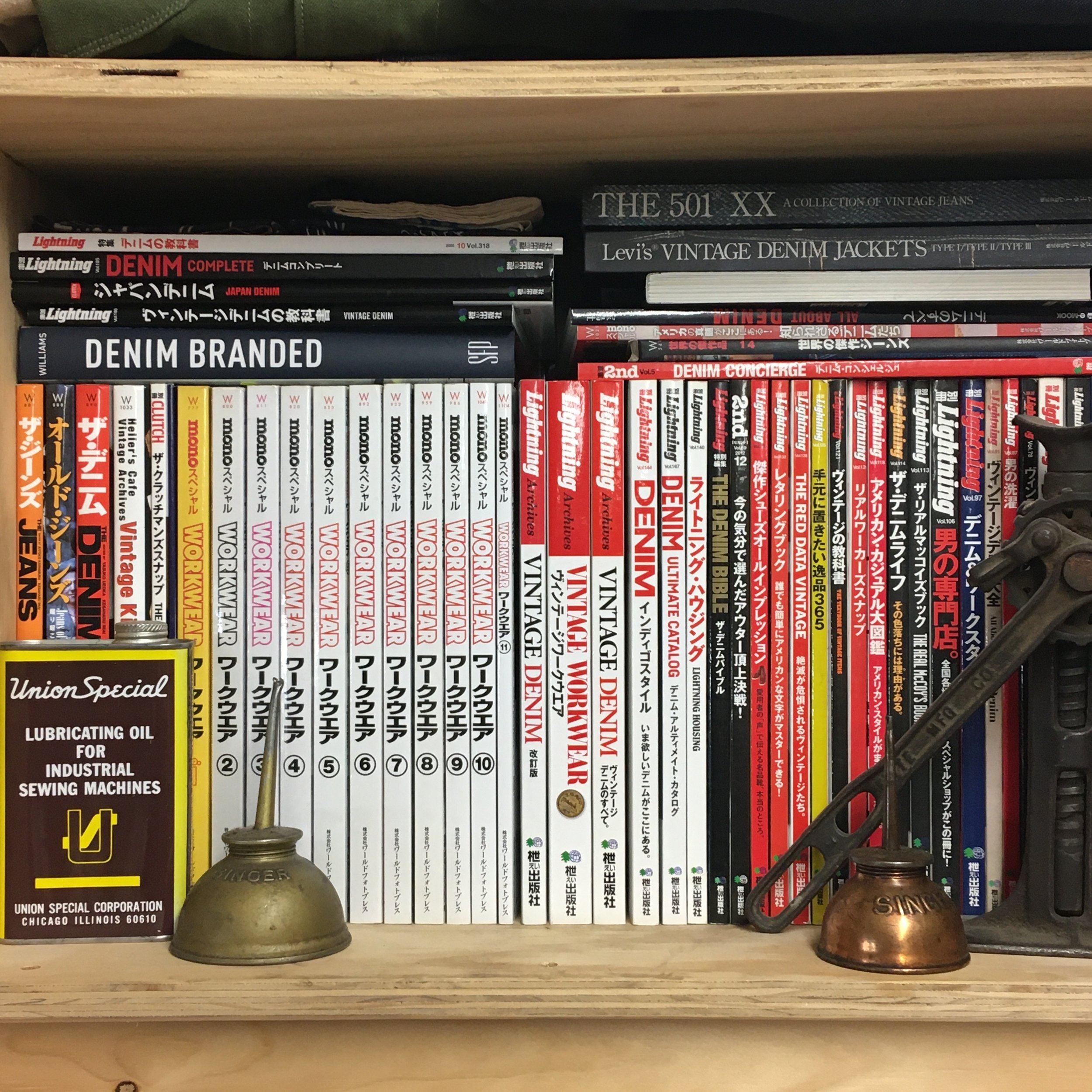

But yeah, you gotta start somewhere. It wasn't until like the old machines, it wasn't until I saw some pictures from the magazines in Japan. I was like, oh, it looks kind of cool, you know, maybe I can find that.

And some of the machines are very specific, you need this one to do a certain thing, and when you find or when you realize that that's the case, then when you go out and look for it, you find all different types of machines and that excited me, I like that.

15- So you did some research to make a pair of jeans from scratch?

Oh yeah, all the time.

There was one guy who bought me that first Japanese magazine, Lightning magazine, you know. And in the back, there was like maybe 3 or 4 pages, but it was like how to make jeans.

The editors of the magazine went to Flathead company and they got to make their own jeans at Flathead Company. So they explained the machines they’re gonna use.

But everything is still in Japanese, so I'm just looking at pictures, hoping for the best. I didn't have a smartphone at this time, you know, I was late for the smartphone game. But you know at that time I'm just looking at pictures and I would bring the magazine to the store and like I want this machine and they'll be like what model number is? I don't know, look at it, you're the guy, you sell it.

So I had to figure it out and finally, they would tell me, this one is this model, this one is this model. And then I would look up more and more and more and try to find the best version, quality, and the oldest or something.

16- Where did you find the first batch of old machines, in Thailand?

Yeah yeah, so the very first machine I got that was the first and last time I bought from that guy because it was like, you know, fake machine just cheap quality. I think the brand new, table, motor, machine, everything was like 200 bucks. You know, it was nothing, I just wanted a deal.

So I just got it.

But the first batch where I got five machines, was from a shop, that was quite close to my house in Thailand, and they sold a lot of industrial machines. It wasn't the biggest shop, but they were very close to home so I would always go visit them and they were very helpful. Even though after a long

time, I realized he was kind of cheating me with the prices, whatever that’s Thailand. I'm a white guy, that's it, you know, white guys pay more.

17- Have you already bought some union special at that time?

In the beginning, I wasn't focused on a specific brand. I didn't have that sort of obsession but I just wanted specific types of machines. Like the 1st order when I got 5 machines, I got a button whole machine and I wanted a Reece machine.

But he ended up giving me a Durkopp machine which was good, and then I got a Brother tacking machine to attach the belt loops and stuff like this and it was a great machine.

I actually just gave it away recently, but that one was great.

Then I got a Kanzai special which is like a Union Special, but the Japanese version.

And that one is for belt loops but I use that one for so many different things because you could put three needles, two needles, one needle with the spreader, no spreader, like so many different variations to this machine, and it was a very strong and good machine so that one is helpful.

18- Why did you decide to focus on older machines, do you think you can make better jeans? One thing to remember is good machines make a good product.

If you have a bad machine, it’s hard to make a good product with a bad machine.

So yes, I like the older machines, but I try to buy the best of what I can find. And I mean, you can see here I have over 100 machines but not all of them are in perfect working order.

Sometimes I buy three machines of the same one to combine into one machine, so it's perfect.

Yeah, I mean even here now I use machines from as old as 1896 until 1991, I think is the newest machine that I have.

19- Do you still continue to have a look to buy new machines?

I'm always looking because there's always something but the grass is always greener on the other side, right?

So I have a machine and it works fine, but maybe there's another one with a nicer paint job or it looks a little bit newer, or instead of the two needles, it’s the three little version.

Oh my God, that's the one I want.

It's a disease, you know, but I like this disease.

20- Are you missing one machine in particular?

No, I have pretty much whatever I need.

Yeah, there are certain machines that would be super cool to use, but a lot of those machines I've never even seen in real life anyway, so...

Well, I mean I have hundreds and hundreds of books and PDFs and images from all these different companies, and wow, there's some crazy machines in there but I've never seen them in real life anywhere, you know.

21- So when you buy the machine, is it come with the motor and the table around? So sometimes you can find a machine like complete with table motor everything.

But my space is pretty confined, so I usually just take the machine head and I'll build my own table and put a new motor. The new motor it's a little bit better with electricity, you can control it easier, and it's also a little bit lighter.

And it's also less risk of fire and stuff. The old machine and old motors are full of dust and dust, maybe from 1943, so you know.

22- When you buy one, do you always clean it?

No, no, I’m not Arthur (laugh). You know if the machine works and looks good like you gotta clean a little bit, you know.

23- How do you know if a machine works perfectly or not, you need to see inside no?

Not necessary well yeah. So when I go and find an old machine sometime the machine doesn't even spin like it's locked like the grease is just turned to like glass almost and you cannot move it. And most people would touch it and say “that's garbage, it doesn't move”.

But old metal is good, it's good quality.

Sometimes I would open up certain things to check like does it has the foot, does it has all the major things that will make the machine work in there. If it's there and they look not completely rusted, then there's a very high chance that it can work again.

Like the second one, right there; when I got it, it was covered in some sort of weird white dust and it didn't move. Like you couldn't spin it, you couldn't twist it, anything.

So I oiled it for a few days and clean it a little bit and when I start to clean it, I was like wow, the paint is beautiful like it has a good chance you know. And once you start to go a little bit and the wheel turns just a little bit, OK, it'll work.

If you leave the oil in the machine for too long and you don't move it, it will, there's a special word I don't know the word for it, but it like it basically turns the glass solidifies and it will lock the machine.

So once you unlock it, it's good to go.

24- So back in the day, you start to make denim for your friend and after that when you launch the business you start to do whatever the customer wants?

When I first started like when I was young, you know like 16 and up I did mostly jackets with Tweed and silk lining and stuff like this. But then when I went to Thailand and didn't make any jackets I started to do more jeans. And in Thailand I mostly jeans, I would say 90% of all the stuff I made was just jeans. I did play around with material like just some tweed or some, you know. I didn't do too much Moleskin there, but you know, just cotton and workwear style materials. When I came to

Canada because we have Four Seasons, there was a lot of difference in weather, you could experiment more with different garments and different materials.

So I use a variety of different materials or whether it be denim, moleskin, chambray, tweeds, wool, or pretty much anything. And then I also play out with different garments.

In Thailand was 90% jeans, here it's maybe 50% jeans and the other 50% is shirts, jackets, and vests.

25- When did you return to Canada?

Now five years ago, in December 2016.

26- Since that day, do you think you are more creative?

A little bit, I mean. It's a tricky one because it's up to my clients. I have an idea, I want to make, but if no one orders it, I mean, unless I make it for myself, but... I do feel that I do a lot of new and exciting things, especially since being back in Canada.

I get to experiment with different garments, so making different styles and stuff. It's been good, been fun.

27- But where do you find your inspiration when you do a jacket with a special curve stitching?

I have some of the weirder pieces that I do, they either come from, you know, old books about denim or something where there's a patent. I don't try to just take it right out of the book and make it, but put my own twist on it or something like this.

I can show you the patent after if you want, but it's like the customer he showed me, I think 4 drawings from the book, and he said take these four ideas and make it into one pair and that's where I got the idea for this style.

It takes a brave customer to decide to pick something that's never been done before, you know?

Most of the time it's like I want 47s 501 or I want basically this or this. When I do a very unique pant, other people will see it immediately and say that's the one I want. And when that happens, it's good.

28- So you can do whatever the customer wants, even the craziest ideas?

There are some ideas that I say no. Like I don't want to embroider profanity or bad words or something. if I think that it's not going to look good at all, I won't do it if the shape they want like super skinny or something, I'll say NO.

“Come on, you know like I want you to wear my jeans for a long time, not just for this season.”

29- You are more specialized in workwear products?

I try to avoid the idea that I'm just another one of those menswear shops like you come in and get something tailor-made like if you want the tailor-made menswear experience, go somewhere else.

You know I make workwear, I try to put a different flavor to it because it's still custom made and maybe bespoke is not your favorite word. But you come, you order, I make a pattern for you and I make your garment.

30- Bespoke and custom-made is it the same for you?

Look up the word bespoke in the dictionary. You know it means made to order.

It depends, how many fittings do you need? If you need more than three fittings, it means you're a bad tailor.

If I can get what you want first try, it might be, that I have something to do with skills and not passion.

Also, my price is reflective of being a boss and getting it done right the first time. If you want five fittings, I'm going to charge you an extra five times.

31- What is the hardest garment that you make?

This style is very challenging. That yeah, that's a hard one, because like when you make a pair of pants, the order never changes. You can make the back before, the front whatever, but when you put it together, it's a specific way. This takes that method and it throws everything out the window.

You have to do some of this, then some of that, then put the front here, then put it on top, and then it's just like, it ruins your order you.

32- For that one for example, is it the customer that said: “I want this”?

Yeah, yeah yeah, I know he picked it, he saw the designs and said I need this one. I said, “damn it, you know it's a hard one to make”.

33- Did he come with a drawing?

Uh, OK, so the first guy that ordered this one showed me the three or four patents in the book and he said “take these and make one piece with this design”.

Since I made that first one for that guy, many people saw this one, because no one can make it. There is no other brand that does this, so you know other people see it though I want that one.

34- When you create the garments, what is the most important detail to keep?

It's a good question because when you’re in a custom business, I'm not making 100 of the same thing over and over and over, it's always different. So each material that I touch is going to move differently under the foot of the machine.

So, an example I can cut the same pattern, same jeans, 10 times with ten materials, it's going to feel different, fit different, look different. When it washes, it's going to shrink differently, so this is very tricky.

Some customers ask me, do you make my pattern and keep my name on it?

Sometimes, but sometimes no, because it doesn't matter if you order seven materials, I'm going to change the shape on all seven, so that it works to your advantage.

35- Do you continue to try new materials, to see how they react when you put them on the washing machine?

After 17 years of making jeans, I have a very good idea of how this material will shrink, move, or what will happen to it when I use it. But yeah, I do like to test it a little bit and it's good to always experiment with the materials.

36- Can you say today that you are able to work with any material that a customer wants?

I want to say yes, but for example, I don't use stretch denim, I don't want to touch stretch denim. Why just I think it's out of principle for me.

A lot of companies use stretch for comfort and for ease of fit. They make the waistband on the stretchy side so that anyone can fit it in between a 30 to 34, so that doesn't take too much skill. When you come here, I want to show you that I know what I'm doing, so pick a material then let me show you.

37- What is the process if I want made-to-measure denim?

I have many different types of customers and there are many different ways of doing it. Sometimes I have people who come here and they say “Ben, I like what you do, just make me something” and I go, what the hell?

So I try like:

Is this material OK? Can I go crazy or do you want very tonal? And I'll ask questions like that.

Sometimes people will give me a huge list like two or three pages of point-form notes, I want this stitch to be like this...

That's it's fine.

Sometimes, you know, on your first pair, I wouldn't recommend being too crazy, because then you're going to have, if you put so many details on your first custom order, there are so many things to look back on and regret, maybe. So sometimes it's better with your first custom order to have a classic garment. Do you want to buy a shirt, pick a nice clean button-up, you know, focus on the

material and the cut. Then on your second order, you can come back and be like “can we add something here?”.

Something like this, maybe change the bar tags to red instead of white, or something like this.

38- Are you only working with selvedge denim?

I don't only work with selvedge, I have other materials that are not selvedge.

But selvedge material, it's nice, it's got a cool story behind it, it's interesting, it's original, kind of fits the theme.

Again, I'm not trying to make that classic menswear vibe. If you want the perfectly tailored trouser to go somewhere else. I make jeans. You know using selvedge is a little bit more rugged, it like, again, it has this story.

So it's fun to use a material that will age and move with you.

It's a very cliché answer, but you know, I like it.

39- Is it easier to work with selvedge denim?

No, I mean my machines are set up in a way that it's easy for me to work with selvedge denim.

But if someone gave me super stretch denim with lycra inside or something like this, my machines would chew it up, it wouldn't work well. So I'd have to re-calibrate them a little bit to handle that better.

I have my shop set up in a way that works for me, it works for what I'm doing.

I do have a lot of different materials on hand or that are available to me and I'm OK with using most of them, as long as they kind of fit the theme.

40- Since the beginning, are you running the business only by yourself or are you helped by someone?

So it's always been like solo ridership. I did have a couple of people working for me over the years. In Thailand, I had the Vietnamese refugee for a little while, he was really good, really helpful. He's super smart, I will show him one time and he would get it.

And then after he left, I had a Thaï guy that would work with me for a little while.

His family actually owns a denim factory, so it was quite interesting that if I had a big project or something that I need to do sometimes, I can get the factory to help me.

And for those that follow me on Instagram, if you saw when I went to Thailand I posted some videos at that factory, so it was kind of fun to go and visit.

And now, since I was been in Canada, I've had a couple of interns.

But you know, I don't hire anyone per say.

Sometimes I get friends to help with alterations and repairs like Jean from (@denim.custom.service).

41- Do you like to transmit your passion to others?

I don't hide my knowledge. Honestly, I don't make a huge amount of money that I can hire 3 or 4 people. I can make enough, I'm doing this full time to support a family of four.

Name someone else in the denim industry who makes jeans by themselves and who does it full time, first of all. And do they support themselves or a family of four?

I'm pretty sure, I'm one of the only ones. My wife doesn't work, my kids don't work, you know so, I need to work hard.

42- So, if I want a garment from you, where can I buy it?

You can either come here, or you can buy online if you feel confident with some of the measuring.

I do have a measuring guide online, and if you're still worried you can always send me photos of you wearing the jeans that you measured, or pictures of measuring the jeans.

But yeah, coming here is always the easiest way to see and feel the material too.

And sometimes, I have extra stuff here that you can't find online, extra buttons, some rivets, and stuff like that.

43- Now, you have customers from all over the world?

Yes, I have clients pretty much everywhere, on all the continents. I have a regular client who drives five hours to see me, three times a year, at least three times a year.

44- How COVID-19 has impacted your business?

I feel very sorry for everyone who has lost something during this time. However, because I'm not a mall brand or I don't have like a storefront, I was able to work from my shop alone. And because I had online orders and a very generous customer base, and also another thing to remember: is that different parts of the world were affected at different times.

So when there was a lockdown in the states or Canada or whatnot, other places have bought in February during Chinese New Year. A lot of orders went to China, and different things happened at different times, so I have to count my blessings and I'm doing great this year, I can't complain.

45- What is your plan for the future, do you have some projects or dreams? Aw man, I have hopes and dreams, but it's very hard to do it. It's very hard to do it alone. I don't know.

OK, so for example, it would be nice to maybe have a few stores.

Let's say for example 2 stores in Asia, 2 stores in Europe, a store in the States, and a store in Canada that would carry a selection of some of my stuff. It doesn't have to be a lot, but it could be maybe like quarterly, they buy 20 pieces and then I would still do some custom.

If I have a big, or at least if all of those stores were selling and maybe the custom prices could rise a little bit, then I would have some time to experiment with other things that I want to do, maybe some hoodies, I don't know.

46- Do you plan to open a store with a shopping window or do you want to keep your “secret place”?

I mean, I want a window but not for you, for me, you know.

Even in Thailand, I had a very nice shop, with nice big windows, but it was so far inside the street, it was very hard to go inside and see it. When the customer got there, I call it having like the found experience, like when you find it, you like “WAAAAOOOOOOOOOO”, you know.

I think this is valuable to a company because if you're in the mall, or if you have a nice Street like you're on Queen Street or something and you have a beautiful storefront, 1000 people walk by every day. But how many people walk in?

No one you know. Five people out of 1000, who cares. But if your shop is hidden when they come, they buy something. When I was super young I used to work in retail, at the skateboarding store and the manager would always talk to us about the ratio of customers who walk in versus customers who buy. And it was always a bad number.

But here, it's one-to-one. If you come here, you're getting something.

Whether it be an alteration or an actual garment, people come here and they buy something.

47- But where people can find you if they don’t know you?

It could be as simple as like, just even Googling. I have a lot of guys who just Google “custom jeans” or like "jeans fit me bad, where do I get like tailor-made jeans custom jeans?”.

But the best way is word of mouth, and I have a lot of people who talk about me on Reddit or these things, Reddit is a very dangerous place, be careful, but it's been OK for me so far.

48- If a customer comes here and knows nothing about denim?

I'll scan them (laugh). I'll try to teach them to the best of my ability. I know that information, is a lot sometimes. I try to gauge: how much they want to learn. And is it valuable for them to learn everything all in one shot? Or just be like, I think you're going to like this. I try to offer them something that they would appreciate.

49- You try to educate them!

I mean, I don't want to sound rude but it's not my job to educate them.

But I do want people to understand what they're getting, so I do explain what I need. If they come in and they want some like crazy heavy jeans, but the jeans they're wearing are 11 ounces, I'm probably not going to sell them to you.

Because it doesn't make sense, you're not going to like it.

So I try to the best of my ability to explain what you're going to get without having to waste, you know, hours and hours to start talking about yarn size versus left-hand or right-hand twills, who cares?

As long as you like the jeans you should be OK.

Eventually, we can go deep.

50- For you, the most important thing is to wear the jeans that you make.

Yeah, as I told you before when I first had to make jeans, I didn't know what selvedge was, I didn't even know the jeans. I knew they faded, but I didn't know that they faded, faded. I thought it was just you design it like that.

Well, I remember the first jeans that came back to me after one year of wearing them, as I made them for my neighbor, and after one year he came back and asked for another one. And I said “Come on, what about the one that I gave you?” and he's like he was wearing them. But I didn't even recognize them, they were so faded.

That was a big shock.

So this sort of idea is that like I didn't know too much going into it, but you don't need to. You just need to know that you like jeans and if you put them on and it feels good on you that should be enough, you know.

You can always nerd out and learn more, but...

51- Are you working with designers?

No, not really. Most people, just take my design from Instagram and remix it a little bit.

52- Do many companies copy you?

I don't want to use the word copy.

But influence or inspire or they say like, “oh that's actually pretty crazy”, maybe we can do it, but then change this a little bit.

It's tricky because I make one pair at a time, each pair is different, so I have a lot of time to experiment with these things and they don't.

53- How long does it take to make jeans?

I usually tell people it takes 1 jeans a day. If I use the same stitching color for three jeans, I can probably, stitch them a little bit faster because everything is similar, but yeah, usually if you include cutting, changing all the thread in the machines, prepping, drawing the pattern, maybe it's one full day at least, yeah.

54- Thanks, Ben, do you have something to add?

I'm pretty chill, when you see someone with the Indigo leaf on the back pocket, it's probably me, yeah.

Thanks man.